For facility managers, plumbing professionals, and maintenance teams, urinal maintenance is often overlooked until it becomes a serious problem. Slow drainage, persistent odors, and clogged urinal pipes aren’t just inconveniences—they signal a deeper mineral scale buildup issue that can disrupt operations, increase plumbing costs, and create ongoing sanitation challenges.

Most standard cleaning products fail to break down urinal scale, leading to frequent blockages and odor issues that keep coming back. That’s why professional facility teams turn to Crete—Brodi’s heavy-duty urinal descaler that is engineered to dissolve calcium deposits and scale buildup at the molecular level.

In this guide, we will break down:

- Why urinal scale forms and how it impacts drainage

- Why traditional cleaners don’t solve the problem

- How Crete works at a chemical level to eliminate scale buildup

- How facility managers can use Crete to reduce maintenance costs

What is Urinal Scale, and Why is It a Problem?

Urinal scale is a hard, rock-like deposit that forms when minerals from water, urine, and cleaning agents accumulate inside urinal drain lines. Over time, these minerals solidify, leading to blockages, slow water flow, and persistent odors that can’t be removed with regular cleaning.

The Science Behind Urinal Scale Formation

Urinal scale is primarily made up of calcium carbonate, magnesium, and uric acid salts. These minerals are naturally present in water and urine, and when they combine in a high-usage environment like urinals, they create thick layers of hardened deposits that coat drain pipes and trap bacteria.

What Happens When Scale Buildup is Ignored?

- Restricted drainage: The scale narrows pipes, slowing down water flow and leading to frequent overflows

- Persistent foul odors: Bacteria and organic waste get trapped in scale layers, making urinals smell bad no matter how often they are cleaned

- Increased plumbing costs: When scale builds up to the point of completely blocking urinal drains, costly plumbing interventions like mechanical snaking or pipe replacements become necessary

- Higher maintenance labor: Without proper treatment, facility teams must constantly revisit the same urinal maintenance issues, wasting time and resources

If urinal scale isn’t removed correctly, the problem will only get worse.

Why Traditional Cleaners Don’t Work on Urinal Scale

Many facility teams attempt to fix urinal scale issues using standard cleaners, but here’s why they fail:

- Surface cleaners only address stains – Many urinal cleaning products are designed to clean the surface of the fixture but don’t penetrate deep into pipes to dissolve scale buildup

- Acid-based cleaners can damage pipes – While some acidic cleaners break down light buildup, they don’t fully dissolve hardened scale and can even corrode older plumbing

- Physical scrubbing is ineffective – Scrubbing the urinal bowl might make it look clean, but the real issue is inside the pipes where scale forms

If the buildup isn’t chemically dissolved at its source, the problem will keep coming back.

How Crete Works: The Only Solution That Fully Eliminates Urinal Scale

Crete is engineered specifically for urinal scale removal. Unlike standard cleaning products, it doesn’t just clean—it chemically dissolves scale at the molecular level.

The Science Behind Crete’s Formula

- High-powered chemical descaling: Crete reacts with calcium carbonate and uric acid salts, breaking them down into water-soluble compounds that flush away effortlessly

- Foam-based action for deep cleaning: Unlike liquid cleaners that simply run down the drain, Crete foams up and expands inside the pipes, ensuring it reaches and dissolves scale in hard-to-reach areas

- Odor elimination at the source: Since urinal scale traps bacteria and organic waste, breaking it down removes the root cause of foul odors, making restrooms smell fresher instantly

- Prevents future buildup: Regular use of Crete keeps urinal pipes clear, reducing the frequency of clogs and odors and extending the life of plumbing systems

Crete is the only solution designed to completely eliminate urinal scale buildup—not just cover up the symptoms.

How Facility Teams Can Use Crete for Maximum Efficiency

Using Crete as part of a regular maintenance routine will prevent urinal scale from becoming a costly, recurring issue.

Application Process

- Ensure the urinal drain is clear of standing water before applying

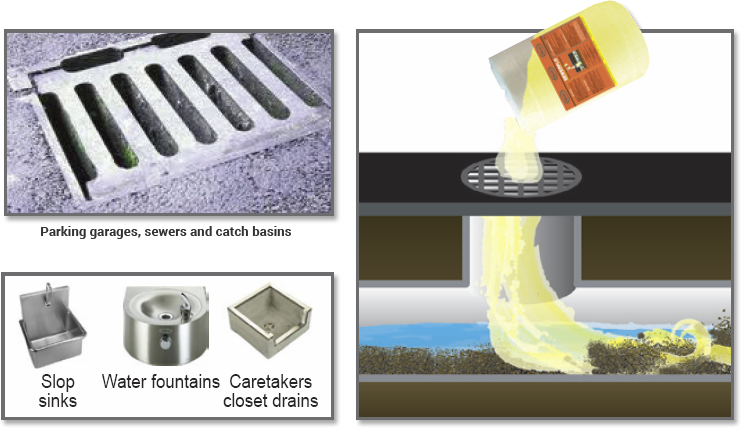

- Pour Crete directly into the urinal drain—its foaming action will expand inside the pipes

- Allow Crete to sit for the recommended time so it can fully dissolve scale deposits, overnight is ideal, just bag the urinal so nobody will use it during the treatment.

- Flush the system thoroughly to remove all loosened buildup

For existing buildup, use Crete more frequently at first until scale is fully removed. For ongoing maintenance, use Crete on a regular schedule to prevent future scale formation and keep urinals clear.

Cost Savings: Why Crete Pays for Itself

- Reduces labor costs: Eliminates the need for constant manual urinal maintenance

- Prevents expensive plumbing calls: Stops urinal clogs before they require professional intervention

- Increases urinal lifespan: Protects plumbing by preventing corrosive mineral buildup

- Creates a better restroom experience: No more odor complaints from employees, customers, or visitors

Facilities that switch to Crete see fewer maintenance issues, lower long-term costs, and cleaner, fresher restrooms.

Stop Urinal Scale Before It Becomes a Costly Problem

Urinal scale is one of the most common yet most neglected plumbing issues in commercial buildings. If it’s not treated properly, it will cause clogs, odors, and expensive plumbing repairs.

Crete is the only solution you need to dissolve scale at the source, prevent future buildup, and keep urinals flowing freely.

Get Crete Today and Keep Your Urinals Scale-Free

- Eliminates 100 percent of urinal scale and buildup

- Prevents slow drainage and persistent odors

- Foam-based formula reaches deep into pipes

- Reduces maintenance labor and costs

Don’t wait for the next plumbing emergency. Get Crete today and ensure clear, odor-free urinals in every facility.

📞 Call us at 1-877-744-0751

📧 Email us at sales@brodi.com

Or visit Brodi.com to place your order.